Next-Gen Logistics and Supply Chain Operations

- INTECH creates intelligent automation platforms, logistics management solutions, and AI-powered supply chain technologies for businesses across domains. Our solutions are designed to enhance fulfillment speed, lower operational costs, and provide real-time visibility.

Transforming Logistics Operations And Supply Chains For Maximum ROI

The logistics and supply chain ecosystem is currently facing challenges such as rising transportation costs, capacity constraints, fluctuating demand, and fragmented data. INTECH provides next-generation supply chain automation software that transforms disconnected operations into unified, predictable, and insight-driven logistics environments.

We design cloud-based platforms for warehouse orchestration, develop transportation optimization engines, and integrate digital workflows. These solutions can be deployed across carriers, fleets, container freight stations (CFS), distributors, ERP systems, and global trade networks. Our solutions aim to improve inventory flow, enhance delivery reliability, and modernize freight execution. It increases efficiency, accuracy, and transparency throughout the entire logistics value chain.

Logistics and Supply Chain Software Development Services

Simplify Logistics and Supply Chain operations through modern software development tailored to specific business needs and objectives. Digital platforms enable greater efficiency, visibility, and operational control across the supply chain.

Warehouse Logistics Software Development

We build warehouse platforms that streamline receiving, inventory accuracy, picking, packing, labor allocation, and fulfillment execution, supporting omnichannel distribution at scale.

- Streamline inbound, putaway, and outbound warehouse operations.

- Enhance visibility with real-time inventory tracking and analytics.

- Improve accuracy and reduce manual errors in order fulfillment.

- Enable dynamic labor allocation and efficiency monitoring.

- Support multi-channel fulfillment with smart warehouse orchestration.

- Boost operational agility through automation and predictive insights.

Sales and After-Sales Mobility Solutions

Mobile-first applications empower field teams, customer service, delivery personnel, and sales operations with digital documentation, status updates, and faster response capabilities.

- Empower field teams with real-time access to sales data and tools.

- Digitize customer interactions, quotes, and order approvals.

- Simplify after-sales service with instant ticket updates and tracking.

- Improve customer satisfaction through faster service turnaround.

- Integrate mobile workflows with CRM and ERP systems seamlessly.

- Boost productivity with GPS-enabled task routing and reporting

Shipping Logistics Management

Automated shipment scheduling, rate comparison, digital booking, compliance workflows, and carrier collaboration improve freight planning and execution.

- Automate shipment scheduling and carrier coordination.

- Compare freight rates and book carriers digitally in real time.

- Reduce manual documentation with end-to-end workflow automation.

- Ensure compliance with shipment and customs regulations.

- Track shipment status, ETAs, and exceptions proactively.

- Improve freight utilization through data-driven planning.

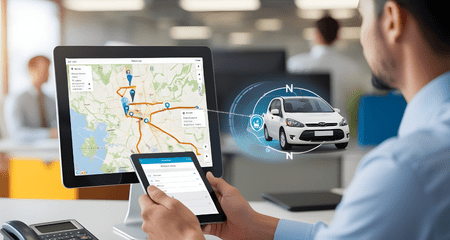

Fleet Management Software Development

Our Fleet platforms optimize routing, utilization, driver performance, predictive maintenance, and real-time vehicle monitoring to reduce transportation costs.

- Optimize routes for time, cost, and fuel efficiency.

- Monitor vehicles in real-time with GPS and telematics integration.

- Predict maintenance needs and minimize downtime.

- Improve driver performance through performance metrics and analytics.

- Reduce the total cost of ownership with utilization insights.

- Enhance safety through intelligent alerts and compliance checks.

Telematics Software Development

We offer IoT-enabled telematics systems that deliver fuel intelligence, engine diagnostics, location insights, driving patterns, and safety alerts across connected fleets.

- Capture live vehicle diagnostics via IoT sensors.

- Generate actionable insights on driver behavior and trip performance.

- Monitor fuel efficiency and detect anomalies instantly.

- Enable geofencing for better operational control.

- Integrate data with ERP, CRM, or fleet management systems.

- Improve safety and compliance through continuous monitoring.

Asset Tracking Software Development

Our advanced tracking systems use RFID, GPS, IoT, and sensors to offer visibility into pallets, equipment, containers, machinery, and in-transit goods.

- Track mobile and fixed assets in real time across facilities.

- Use RFID, GPS, IoT, and sensors for end-to-end asset visibility.

- Prevent loss and theft with geofencing and alerts.

- Monitor asset utilization to reduce idle time and wastage.

- Simplify audits with automated asset reconciliation.

- Access dashboards for lifecycle management and analytics.

Supply Chain Management Solutions

We build AI-supported supply chain management platforms for forecasting, procurement, logistics planning, network optimization, and performance analytics.

- Streamline procurement, inventory, and transportation in one platform.

- Harness AI to forecast demand and optimize resources.

- Improve supplier collaboration and sourcing agility.

- Gain full visibility across logistics and distribution networks.

- Automate workflows from planning to performance analytics.

- Reduce costs through smarter network design and decision intelligence.

Logistics and Freight Audit Management

Our solutions offer automated invoice validation, freight payment processing, charge discrepancy detection, and financial reconciliation to ensure billing accuracy.

- Automate freight invoice validation and matching.

- Detect charge discrepancies and prevent overpayments.

- Simplify freight payment processing and reconciliation.

- Centralize billing data for multi-carrier operations.

- Improve financial transparency with real-time audit trails.

- Enhance accuracy with AI-powered validation workflows.

Parking Management Software

We offer yard and parking automation systems that reduce congestion, manage truck appointments, and streamline entry/exit operations at logistics hubs.

- Digitize yard and dock scheduling for smoother traffic flow.

- Manage truck appointments and entry-exit with automation.

- Improve space utilization through smart parking allocation.

- Reduce congestion and wait times at logistics hubs.

- Integrate with warehouse and dispatch systems seamlessly.

- Boost safety and visibility within high-volume yards.

Dispatch Management Software

Centralized dispatching with our custom software solution enables task assignment, real-time fleet tracking, customer notifications, and optimized delivery routing.

- Assign and track tasks through a unified dispatch dashboard.

- Optimize fleet routes with AI-driven delivery planning.

- Provide customers with real-time ETA updates.

- Improve driver productivity via mobile connectivity.

- Enable instant communication between dispatchers and drivers.

- Scale operations with analytics-backed decision-making.

International Trade Compliance Software

We create advanced digital trade systems to manage customs workflows, documentation, tariff validation, classification, and cross-border regulatory compliance.

- Automate customs documentation and clearance workflows.

- Validate tariffs, HS codes, and trade classifications.

- Ensure end-to-end compliance across global shipments.

- Integrate with ERP and trade platforms for real-time visibility.

- Reduce compliance risks through rule-based automation.

- Simplify global trade operations with centralized digital systems.

Fintech Innovations

We offer payment automation, freight financing, insurance digitization, escrow workflows, and embedded financial systems to support logistics transaction efficiency.

- Automate payments for logistics and freight settlements.

- Enable freight financing and flexible credit solutions.

- Digitize insurance and claims for logistics assets.

- Manage escrow transactions for multi-party logistics deals.

- Embed financial workflows into supply chain operations.

- Ensure transparency with secure, compliant payment systems.

INTECH's Logistics and Supply Chain Solutions

Unified CFS Operations Platform

At the core of Container Freight Station Management is a centralized digital platform that connects gate operations, cargo tracking, yard and warehouse management, billing, and documentation. This unified environment eliminates siloed spreadsheets and manual handovers, enabling seamless coordination across internal teams, customs, and external logistics partners.

By consolidating all CFS workflows on a single interface, operators gain a clear, real-time view of inbound, storage, and outbound activities. This reduces errors, minimizes rework, and improves the overall velocity of cargo through the station.

Intelligent Cargo Intake and Documentation

Automated workflows streamline cargo intake, digital documentation, gate pass creation, and invoicing. The system validates key fields, auto-populates repetitive information, and enforces document completeness before movement, reducing processing delays and compliance risks.

As a result, staff spend less time on manual data entry and paper checks, while customers benefit from faster processing and fewer documentation-related disputes. This directly improves cash flow and service reliability for LCL and FCL flows.

Real-time Cargo Visibility and Tracking

The platform provides continuous visibility into cargo location, status, and yard or warehouse occupancy. Operators can see which shipments are awaiting stuffing, which are ready for destuffing, and how capacity is distributed across sheds, yards, and bays.

Real-time visibility supports faster, more confident decision-making, optimizing space utilization, reducing dwell times, and preventing congestion in key areas. This transparency also improves coordination with transport and shipping line partners.

Streamlined CFS Workflows

All major freight station activities, gate-in and gate-out, stuffing, destuffing, consolidation, deconsolidation, and transloading, are managed through a single interface with clear task flows and status updates. Standardized digital workflows reduce process variance between shifts and locations.

Supervisors can monitor work queues, reassign tasks, and respond quickly to bottlenecks, keeping operations predictable and aligned with vessel and truck schedules. This leads to more efficient turnaround and higher throughput.

Customer and Partner Self-service Portals

Integrated portals enable customers, freight forwarders, and partners to submit service requests, upload documents, track cargo status, and download invoices or gate passes. Automated notifications keep stakeholders informed without constant follow-ups.

Self-service access improves transparency and reduces inquiry volume to operations and customer service teams. It also strengthens relationships by providing real-time, reliable information on cargo progress and charges.

Operational Analytics and Insights

Built-in dashboards deliver visibility into throughput, dwell time, gate cycle performance, utilization, and revenue metrics. Managers can identify recurring bottlenecks, underused capacity, and margin leakage points across services and customers.

These insights support continuous improvement initiatives across staffing and layout decisions, tariff optimization, and SLA refinement. Over time, CFS operations become more predictable, efficient, and profitable.

Unified transport operations platform

At the core of the Transport Management System is a centralized digital platform that brings together shipment booking, planning, execution, carrier management, and financial workflows. This unified environment replaces disconnected tools and manual processes, enhancing coordination across shippers, carriers, forwarders, and consignees.

Stakeholders work from the same data set for orders, routes, capacity, and costs, reducing miscommunication and duplication of effort. This shared visibility is critical for managing high shipment volumes and complex multi-leg routes.

Intelligent route and load planning

Advanced planning logic evaluates delivery requirements, lanes, vehicle capacity, carrier constraints, and service priorities to create optimized transport plans. The system can consolidate compatible loads, select optimal modes, and sequence stops to minimize empty miles and transit times.

This improves fleet utilization and lowers fuel and transportation costs while maintaining or improving on-time performance. Organizations typically see better adherence to SLAs and fewer costly expedited moves when using a modern TMS.

Real-time shipment visibility and tracking

The TMS provides continuous visibility into shipment status and vehicle movement through GPS, telematics, and carrier integrations. Real-time tracking allows logistics teams to monitor progress, detect delays early, and respond quickly with mitigation actions or updated ETAs.

This level of transparency builds trust with customers and internal stakeholders, while also enabling dynamic re-planning when disruptions occur. Over time, better visibility supports more accurate planning and demand forecasting.

Automated freight billing and compliance

Automated billing and audit workflows validate freight charges against contracts, tariffs, and actual movement data. The system manages documentation, rating, and dispute workflows, ensuring accurate costs and timely settlement with carriers and customers.

Compliance with regulatory requirements and trade documentation is supported through standardized digital templates and validation rules. This reduces administrative effort, billing discrepancies, and the risk of non-compliance penalties.

Carrier and partner collaboration

Integrated connectivity with carriers and logistics partners enables seamless communication and data exchange for bookings, status updates, and proof of delivery. Shared portals and EDI/API connections keep all parties aligned around shipment plans and events.

Automated notifications and shared visibility into performance data support better collaboration and more objective carrier scorecards. This helps organizations build stronger, performance-based partner ecosystems.

Operational analytics and insights

Built-in dashboards provide insight into transportation costs, delivery performance, carrier efficiency, asset utilization, and service levels. Logistics leaders can identify high-cost lanes, chronic delay points, and underperforming partners using empirical data.

These insights inform strategic decisions on network design, carrier mix, and contract negotiations, as well as day-to-day optimization of routes and capacity. Continuous improvement becomes a standardized practice rather than an ad-hoc initiative.

Unified warehouse operations platform

At the heart of the Warehouse Management System is a centralized platform that orchestrates inbound, putaway, inventory control, picking, replenishment, packing, and shipping workflows. It connects seamlessly with TMS, CFS, ERP, and eCommerce systems to ensure end-to-end data continuity.

This unified orchestration reduces manual coordination between departments and eliminates blind spots in stock and task visibility. Warehouse managers gain a live view of work queues, resource utilization, and dock activity in one interface.

Intelligent inventory and storage optimization

The WMS maintains real-time inventory visibility at the location and SKU level, using barcode, RFID, or IoT devices to track every movement. AI-driven inventory optimization and slotting recommend ideal storage locations based on velocity, size, and handling characteristics, improving pick efficiency and space utilization.

These capabilities reduce stockouts, excess inventory, and mispicks, unlocking working capital while improving service levels. Self-optimizing inventory policies keep safety stock and reorder parameters aligned with actual demand and lead-time variability.

Optimized picking, packing, and task management

Advanced wave, batch, and zone picking strategies are supported to match different order profiles and service commitments. The system dynamically assigns tasks to workers or automation systems based on priority, proximity, and workload, minimizing travel time and congestion.

Guided workflows through handhelds or voice systems reduce errors and training time, while standardized packing and labelling processes ensure compliance with customer and carrier requirements. This leads to faster, more accurate order fulfillment.

Real-time exception handling and quality control

The WMS continuously monitors operations for exceptions such as missing scans, inventory mismatches, or delayed tasks and triggers alerts and corrective workflows. Supervisors can intervene early, reroute work, or adjust priorities before issues escalate into customer-impacting problems.

Integrated quality checks at key stages (receiving, picking, packing) help maintain accuracy and reduce returns. This tight control loop enhances reliability and protects margins in high-volume environments.

Integrated labor and resource utilization

Labor management capabilities track productivity at the worker, team, and shift levels, highlighting where additional training, process changes, or automation may be needed. Task and travel optimization reduces unnecessary movement, supporting safer and more ergonomic work patterns.

By aligning labor allocation with demand patterns and service priorities, warehouses can handle peaks more effectively without permanent overstaffing. This improves cost per order and overall workforce efficiency.

Warehouse analytics and continuous improvement

Built-in analytics provide visibility into fill rates, order cycle times, pick accuracy, space utilization, and labor productivity. Trends and anomalies are surfaced through dashboards and alerts, helping managers target improvement initiatives with the greatest impact.

Over time, these insights support data-driven decisions on layout changes, automation investments, and policy adjustments. The warehouse evolves from a cost center into a strategic asset that supports faster, more reliable supply chain performance.

Outcome-driven warehouse performance

By digitizing and optimizing end-to-end warehouse workflows, the Warehouse Management System reduces operational cost, increases inventory accuracy, and improves fulfillment speed. Organizations can support omnichannel, B2B, and value-added services from the same facility without losing control or visibility.

As part of INTECH’s Logistics & Supply Chain Solutions, the WMS works in concert with CFS and TMS capabilities to deliver an integrated, high-performance logistics stack enabling responsive, data-driven supply chains that scale with business growth

Ready to scale smarter and faster? Let's build solutions that drive real impact.

From concept to execution, we help you innovate smarter. Let’s make your vision a reality.

Why INTECH Leads the Future of Digital Logistics & Supply Chain Technology

We help logistics companies, warehouses, and freight operators drive automation, reduce waste, and increase delivery reliability through intelligent data-driven systems.

Proven Expertise in Supply Chain & Logistics Engineering

Trusted by logistics management consulting services, distribution networks, carriers, and CFS operators, we specialize in terminal supply chain integration solutions and scalable digital ecosystems.

Partnership Focused on Real Operational Outcomes

We collaborate with business leaders to align systems with regulatory demands, operational constraints, customer expectations, and long-term supply chain strategies.

Advanced Technology Architecture for Modern Logistics

Operational Efficiency & End-to-End Freight Visibility

Full-Spectrum Supply Chain Digital Transformation

From consulting, modernization, and integrations to implementation and optimization, we support organizations transitioning from manual workflows to intelligent automation.

Technology That Powers Smart Logistics & Connected Supply Chains

Modern logistics runs on real-time intelligence, automation, and connected data ecosystems, and INTECH engineers these capabilities end-to-end. By combining AI, IoT, cloud, analytics, and automation, INTECH helps logistics providers reduce operational costs, improve delivery performance, and build resilient, scalable supply chains.

- Artificial Intelligence (AI)

INTECH embeds AI into fleet management, freight planning, and transportation workflows-automating routing, load balancing, demand forecasting, SLA adherence, and exception handling to accelerate decision-making.

- Machine Learning

- IoT-Enabled Logistics

- Cloud-Native Supply Chain Infrastructure

- OCR & Computer Vision

- Blockchain for Trade & Logistics

- Digital Twin for Logistics Network Optimization

Digital replicas of warehouses, transport routes, and distribution networks help simulate disruptions, evaluate capacity, model demand variations, and plan proactive operational strategies.

Ready to Turn Challenges into Opportunities?

Let’s connect and create solutions that work for you.

Performance Outcomes Delivered

- 38% Reduction in Transportation Costs

- 45% Faster Warehouse Fulfillment Cycles

- 55% Lower Manual Data Entry & Documentation Time

- 33% Improved Forecast Accuracy Using AI Models

- 2× Increase in Fleet Utilization Efficiency

- Significant Decrease in Delivery Exceptions & Service Failures

Trusted Logistics & Supply Chain Partner For Global Clients

Years of Cross-Industry Experience

Driving innovation for enterprises in retail, logistics, ports, manufacturing, and beyond.

Technology Experts

A diverse team of specialists delivering scalable and advanced IT solutions.

Delivery Locations Across the Globe

Ensuring seamless project execution and 24/7 support worldwide.

Case Studies

Discover cutting-edge ideas and insights from the world of technology and business.

Blogs

Discover cutting-edge ideas and insights from the world of technology and business.

Logistics & Supply Chain

Freight Forwarding ERP

Logistics & Supply Chain

FAQs

Do you offer custom-built logistics management solutions?

Yes. We provide tailored WMS, TMS, CFS, audit automation, tracking systems, and enterprise-grade supply chain platforms for logistics businesses.

Can your technology integrate with ERP, CRM, and legacy logistics tools?

Absolutely. We support SAP, Oracle, Microsoft Dynamics, port systems, EDI, customs platforms, and API-led integrations.

What improvements can companies expect from digital logistics systems?

Organizations typically achieve faster fulfillment, reduced operational costs, optimized fleet performance, fewer delays, and improved customer satisfaction.

Do your solutions support multi-location or international supply chains?

Yes. Our cloud architecture enables centralized control, performance monitoring, and standardized governance across regional and global logistics operations.