A UAE-based logistics and supply chain leader servicing industries across the APAC region

Third-party logistics (3PL), warehousing, and freight management

Multi-warehouse storage, order fulfillment, last-mile delivery, and reverse logistics services

Replace fragmented, manual systems with an integrated OMS and WMS to enhance speed, accuracy, and scalability across operations

Manual data entry, delayed order handling, and frequent inaccuracies

Lack of OMS-WMS integration resulted in stock mismatches and order fulfillment delays

Legacy systems couldn't keep pace with increasing order volumes and warehouse expansion

Delayed shipments and incorrect orders impacted service reliability and client retention

Automated order capture and routing through OMS enabled faster intake, prioritization, and SLA-based fulfillment tracking

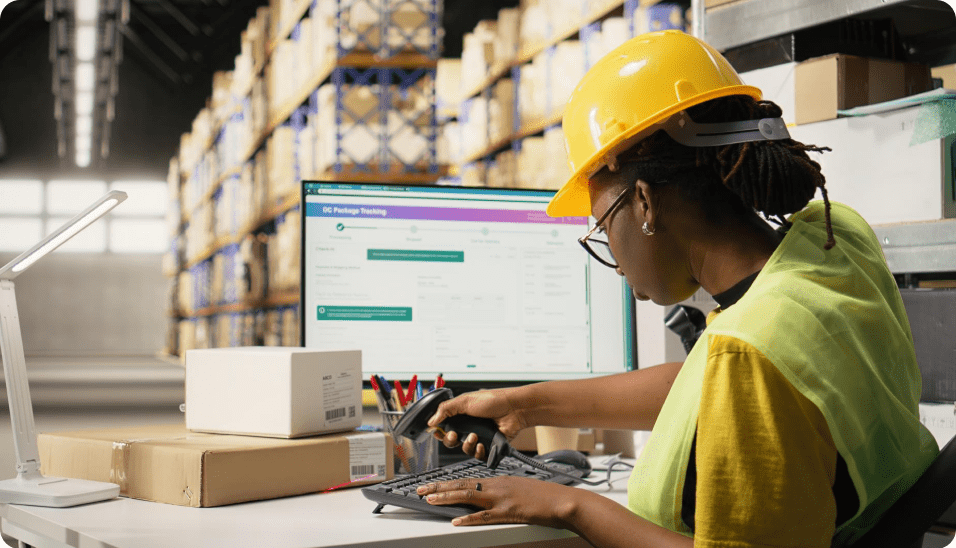

The WMS optimized warehouse activities with barcode tracking, guided put-away, and automated bin allocation for faster movement

Real-time data flow ensured synchronized stock visibility and order updates across all warehouse locations

Designed for multi-client and multi-site operations, enabling expansion without complexity or performance trade-offs

Real-time dashboards and audit trails provided transparent insights into inventory, fulfillment, and delivery status

Centralized order routing, tracking, and automation improving processing accuracy and speed

Real-time inventory visibility, optimized picking, and dynamic put-away for operational efficiency

Automated stock identification and movement tracking reduced manual dependency

Continuous validation maintained accurate stock levels across all warehouses

Unified order, warehouse, and inventory data for seamless operations and actionable insights

Automation synchronized order-to-dispatch cycles across warehouses

System-guided workflows eliminated manual errors and fulfillment discrepancies

Integrated return handling accelerated replacements and refunds

OMS-WMS integration provided real-time order and stock tracking

Centralized platform supported rapid growth and multi-warehouse expansion

Automated OMS-WMS workflows shortened fulfillment and delivery cycles

Intelligent routing and picking ensured precision across all warehouse operations

Integrated reverse logistics streamlined refunds and replacements

Unified platform supported consistent performance across locations

Reduced manual workload, freed staff to focus on customer experience and service innovation

You’re one step away from building great software. This case study will help you learn more about how Simform helps successful companies extend their tech teams.

Discover cutting-edge ideas and insights from the world of technology and business.

You’re one step away from building great software. This case study will help you learn more about how Simform helps successful companies extend their tech teams.