This is a large manufacturing firm which has several production plants in its network

High-volume, complex discrete manufacturing with stringent quality and uptime requirements

Two-line, fast-speed manufacturing based on the use of critical machinery, accurate process control, and closely controlled production schedules

Replace legacy, siloed monitoring and reporting with a real-time dashboard that unifies KPIs, reduces unplanned downtime, and improves overall equipment effectiveness (OEE) across plants

KPIs scattered across PLC logs, local apps, and spreadsheets made it difficult to see a single, trusted view of plant performance

High-volume sensor data from machines could not be effectively ingested, normalized, or analyzed, leaving early warning signs buried in raw streams

It was the case where maintenance teams were not informed of any live alerts or trends so they would only react when things failed, this resulted in frequent breakdown and long-term production stoppage

End-of-shift reporting and end-of-day reporting compilation took hours and leaders had to make decisions based on old and incomplete information

With the addition of new lines and facilities the legacy stack was not able to add new data sources, preventing the uniform visibility of KPIs across the network

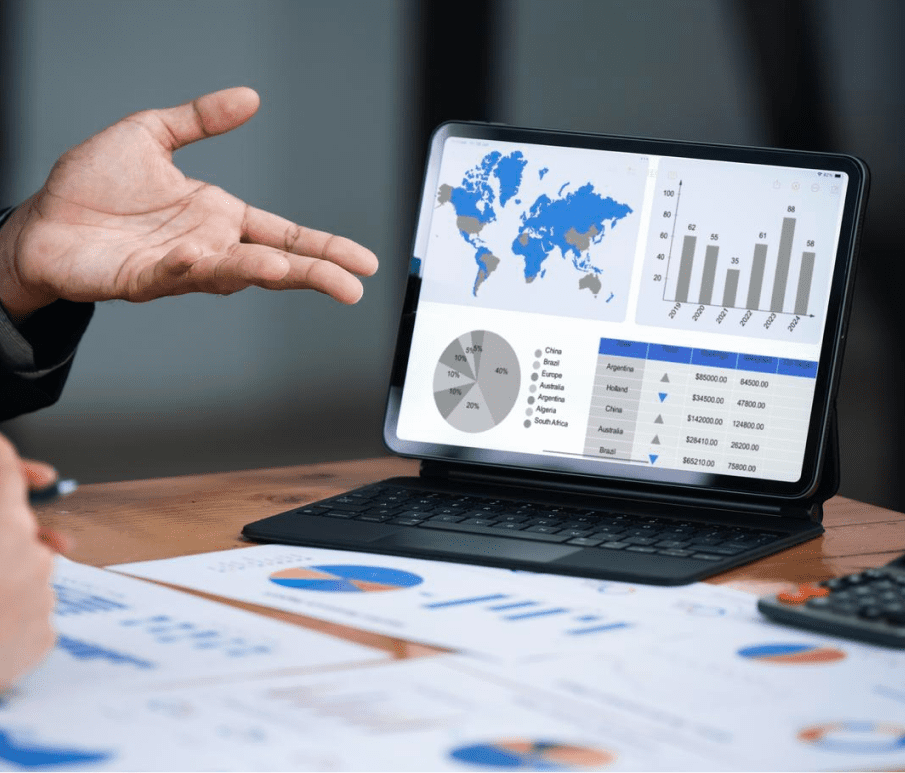

IoT and PLC data streamed into a central dashboard for live visibility into machine health, line status, and throughput

Machine learning interfaces observed the trends and raised early warnings enabling the maintenance personnel to take action before the breakdown and minimize the number of unplanned stoppage

Operator, maintenance lead, managers, and executive-specific views made sure that each of the roles only saw the KPIs and the drill-downs they needed

Unified, Intercompany and Cross-Plant KPIs on a single interface, siloed reports are removed, and tracks the performance across all plants and all shifts

Clean layouts, clear hierarchies, and simple filters made complex data easy to read, driving rapid adoption across teams and shifts

ETL engine ingesting high-volume IoT and PLC data, cleaning and unifying it into analysis-ready streams for real-time and historical insights

Reliable connectors linking shop-floor sensors and controllers to the central platform, ensuring continuous capture of machine, line, and energy data

Single source of truth for live and historical production metrics, enabling trend analysis, root-cause investigations, and cross-plant benchmarking

Interactive dashboards turning complex operational data into intuitive views, helping teams monitor KPIs, spot bottlenecks, and act quickly

Analytics layer detecting anomalies and early warning signals, triggering alerts that support proactive maintenance and protect critical equipment

Real-time monitoring and notifications allowed the maintenance teams to act in time and ensure that minor problems do not develop into complete breakdowns

It was possible to see the bottlenecks and repetitive slows downs and allow the teams to reload the loads, simplify the workflow, and increase the throughput

Cohesive access to availability, performance, and quality enabled improved scheduling, maintenance planning, and used the available resources

Plant leaders now had one place to go to get the truth about line status, machine health and shift performance, in real time in multiple plants

Live KPIs over stagnant reports: decisions regarding capacity, maintenance windows and staffing became faster, more evidence-based and sharper

Live machine monitoring and alerts helped teams to intervene early before potential breakdowns could occur by transforming them into swift, scheduled interventions

Bottlenecks and frequent sluggings were also visible in real time, which helped the leaders to reassign loads and keep the lines moving without interruptions

Unified visibility of availability, performance and quality enabled smarter scheduling and maintenance, and taking more out of the current assets

Always-on KPIs replaced static reports, giving managers a single source of truth for capacity, maintenance, and shift planning

Standardized dashboards and role-based views aligned operators, maintenance, and leadership on shared metrics and clear accountability

You’re one step away from building great software. This case study will help you learn more about how Simform helps successful companies extend their tech teams.

Discover cutting-edge ideas and insights from the world of technology and business.

You’re one step away from building great software. This case study will help you learn more about how Simform helps successful companies extend their tech teams.