Most retailers operate supply chains designed for yesterday’s consumer. Demand feels impossible to predict. Inventory balancing plays like a losing game. Customers expect product availability, fast shipping, and rock-bottom prices, all simultaneously. Here’s the thing: generative AI is changing that game fundamentally.

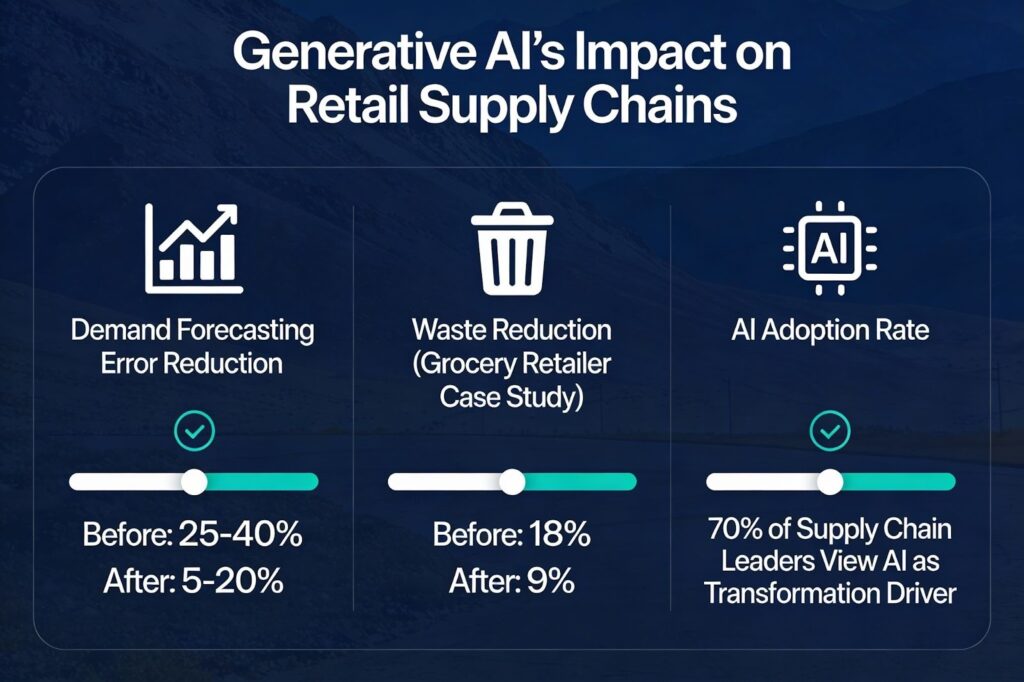

By cutting demand forecasting errors from 25-40% down to just 5-20%, retailers aren’t merely tweaking operations, they’re reimagining how supply chains work. Unlike traditional systems that analyze only historical sales data, generative AI retail platforms integrate real-time weather patterns, social media sentiment, competitor pricing, and market signals. This isn’t incremental improvement. A grocery retailer we know cut waste from 18% down to 9% in six months. That’s the difference between surviving and thriving.

Here’s what’s happening across retail right now: Companies are waking up to generative AI retail’s potential in supply chains. The shift is accelerating. Walmart and Nestle aren’t experimenting anymore, they’re scaling. And 70% of supply chain leaders now view AI as the primary transformation driver for the next three to five years.

The AI Supply Chain Revolution: What’s Changing in Retail Today

The market numbers tell part of the story. The World Economic Forum expects retail AI investment to surge to about US$31 billion by 2028. Global retail leaders such as eBay, Walmart, and Nordstrom already use Generation AI (Gen AI) across a wide range of applications. This growth is significantly larger as enterprises demand intelligent systems. But numbers don’t capture the real story.

In practice, retailers face a brutal reality. Traditional forecasting achieves 60-75% accuracy, meaning roughly one-third of forecasts miss the mark entirely. When forecasts are too high, warehouses overflow with unsold inventory. When they’re too low, customers find empty shelves. That frustration? It drives customers elsewhere.

Legacy systems can’t keep pace with modern retail because they operate on outdated cycles. Inventory audits happen daily or weekly. Forecasts generate monthly. Meanwhile, demand shifts in hours. Data lives trapped in isolated silos, inventory systems can’t talk to sales systems, which can’t reach supplier platforms. By the time humans notice a problem and respond, the opportunity has evaporated.

Here’s the competitive reality: Early adopters implementing AI in supply chain operations are capturing market share while traditional retailers struggle. Companies that move decisively toward AI now are reinvesting profits into technology, pulling further ahead each quarter.

What Generative AI Actually Does Differently

Beyond Traditional AI: A Real Comparison

Generative AI represents a genuinely different approach to forecasting and decision-making. Traditional machine learning? It analyzes historical patterns. It asks: “Based on what happened before, what happens next?” That works until it doesn’t, until an unprecedented event (think pandemic, supply disruption, viral trend) breaks the model.

Generative AI asks different questions. It analyzes causality. It integrates weather forecasts, social media trends, competitor moves, economic indicators, and dozens of other real-time signals. When rain is forecasted in a region, AI automatically correlates that data with umbrella demand, adjusts inventory levels across specific store locations, and recommends pricing based on competitor activity. This all happens in seconds, without human intervention.

The learning never stops. Traditional systems require retraining on new data. Generative AI systems continuously absorb new information and adjust decisions incrementally. This means AI demand forecasting becomes progressively more accurate over time. Retailers can even ask “what if” scenarios and receive detailed simulations showing how different decisions would play out.

Why Now? Why Not Wait?

Supply chains have become dramatically more volatile. Geopolitical instability. Climate events. Consumer behavior shifts. These disruptions occur constantly, and reaction time keeps shrinking. Meanwhile, customer expectations have skyrocketed. People demand immediate product availability, two-day delivery, and seamless experiences across channels.

Legacy systems simply can’t deliver. They’re fragmented. Data quality is inconsistent. Manual processes introduce errors. The infrastructure that worked for steady, predictable demand in 2010 collapses under 2025’s complexity.

But there’s more to it. Competitors are already moving. When Walmart deploys AI across procurement and forecasting, when Amazon optimizes logistics through predictive analytics, when Nestle cuts replenishment times, they’re not just improving margins. They’re reshaping customer expectations. They’re setting new performance standards that industry-laggards suddenly can’t meet.

Five Supply Chain Decisions Transformed by AI

1. Demand Forecasting That Actually Works.

Here’s what typical demand forecasting looks like: Analysts examine historical sales data, account for seasonal patterns, maybe factor in last year’s promotions. Then they produce a forecast. Except? One in three forecasts misses actual demand significantly.

Generative AI changes this. By integrating weather data, social media sentiment, competitor pricing, planned campaigns, and economic indicators, AI demand forecasting reduces error rates from 25-40% down to 5-20% in real scenarios. Some advanced implementations reach 80-95% accuracy.

2. Inventory That Adjusts Automatically

Traditional inventory systems use static reorder points. When inventory hits a predetermined level, an order triggers automatically. That approach ignores real-time demand shifts and creates predictable inefficiencies.

Generative AI calculates optimal inventory dynamically. The system analyzes lead times, demand volatility, product shelf-life (critical for perishables), regional sales patterns, and current supply conditions. As situations change, the system adapts. If demand spikes are forecasted next week, safety stock increases automatically. If supplier lead times extend unexpectedly, reorder points adjust upward to prevent stockouts.

What’s the result? Retailers cut inventory levels by 15-20% while simultaneously improving fill rates to 97%+ and reducing waste. For grocery and food retailers? AI-driven inventory management reduces food waste by 20-49%. That directly improves margins and strengthens brand reputation among sustainability-conscious consumers.

3. Smarter Supplier Relationships

Procurement typically involves relationship-dependent decision-making. You work with suppliers you’ve always worked with. You negotiate contracts once yearly. You accept whatever lead times they offer.

AI transforms this. Automated analysis examines delivery reliability, quality metrics, price competitiveness, payment terms, and risk factors for each supplier. The system creates comprehensive scorecards showing exactly which suppliers deliver value and which underperform.

More importantly? Generative AI automates supplier negotiations. Autonomous agents handle vendor discussions armed with real-time market data, competitive pricing intelligence, and predictive analytics. The result: Companies achieve 4-7% reductions in procurement spend, with some reporting savings as high as 40% when combining multiple optimization strategies.

Lead time prediction represents another breakthrough. AI forecasts when suppliers face delays and recommends proactive order adjustments before disruptions cascade through your supply chain.

4. Dynamic Pricing That Maximizes Margin

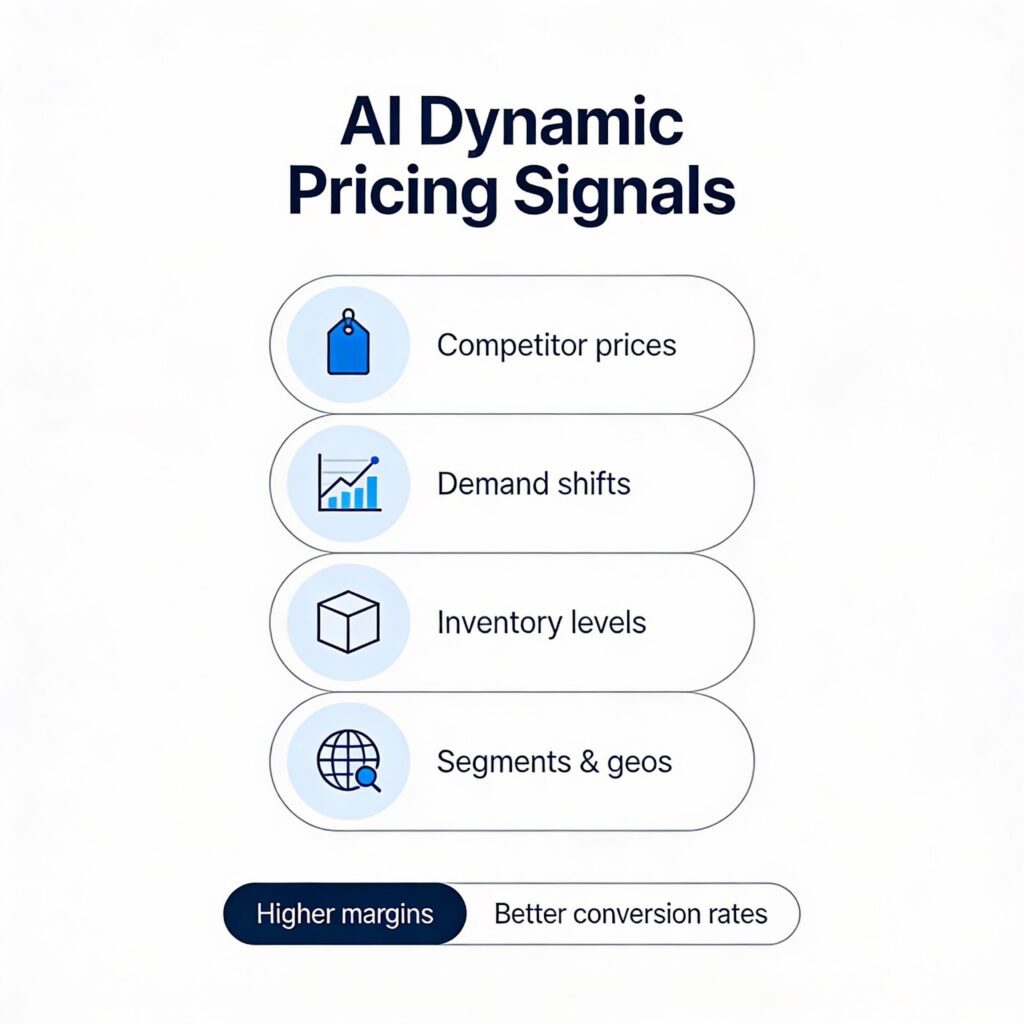

Most retailers adjust prices monthly or seasonally. AI does it differently, continuously and intelligently. The system monitors competitor pricing, analyzes demand fluctuations, checks inventory levels, and calculates optimal prices in real time.

When inventory is high and demand is low, prices decrease to drive sales and improve turnover. When inventory is tight and demand surges, prices increase to maximize profitability. For eCommerce businesses, prices adjust instantly across customer segments and geographies.

Retailers implementing AI dynamic pricing report profitability increases, with improved margins and conversion rates documented. For luxury retailers? The gains are even more dramatic because pricing precision captures higher customer willingness-to-pay.

5. Logistics That Runs Smarter

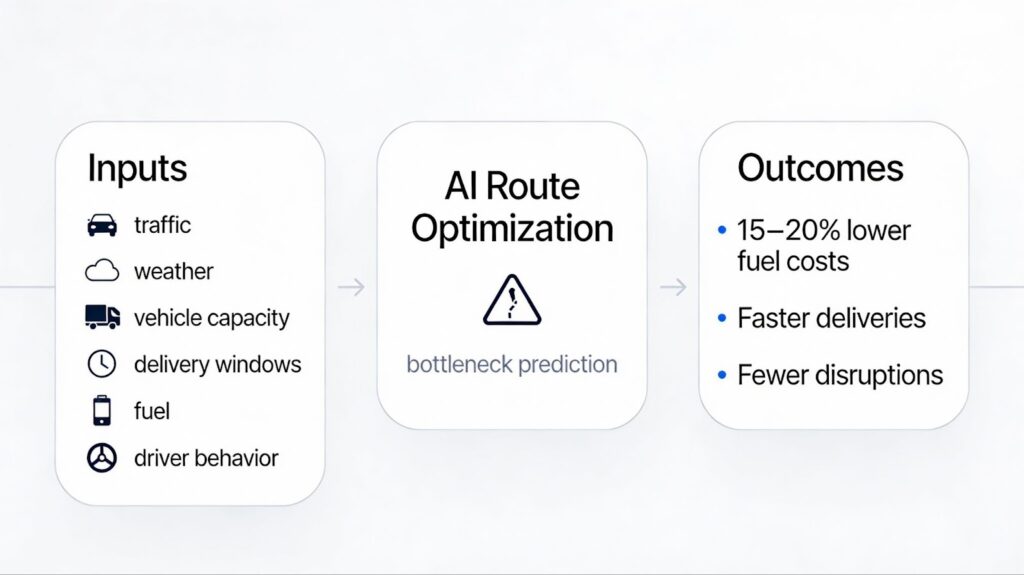

GPS routing is useful but limited, it finds the shortest geographic path. AI route optimization considers traffic, weather, vehicle capacity, delivery windows, fuel consumption, driver behavior, and predicts future conditions.

Companies deploying AI-driven logistics report fuel cost reductions of 15-20%. Some achieve even greater savings through improved vehicle utilization and reduced maintenance costs. Beyond fuel? Optimized routes reduce delivery times, improve on-time performance, and enhance driver safety.

The best part? AI predicts logistics bottlenecks before they occur. Shipments get rerouted proactively, preventing disruptions from cascading through your entire supply chain.

The Real Business Impact

What Savings Actually Look Like

Imagine cutting labor costs by 15-20% overnight. That’s what retailers achieve through intelligent scheduling and retail automation powered by AI. Staff freed from repetitive data entry and manual forecasting? They handle supplier relationships, solve complex problems, and serve customers, work that actually drives competitive advantage.

Processing times shrink dramatically. Manual order processing that took a full business day now happens in one hour. Error rates decline. Why? Because humans don’t handle the transaction; the system does.

Revenue Actually Increases

This isn’t just cost-cutting. Companies report sales increases of 6-10% when implementing AI supply chain optimization. Why? Because products stay in stock. When customers find what they want, conversion rates improve. Repeat purchases increase.

Stock turnover improves from 1.9 to 2.5. That means inventory recycles faster, capital gets deployed more efficiently, and the risk of markdowns and obsolescence decreases significantly. For retailers with fast-moving consumer goods? This difference is the difference between profitability and struggle.

Customers Stay Loyal

When products are reliably available, something changes. That frustration customers felt? It disappears. Fill rates at 98%+ mean customers find SKUs in stock almost always. Faster delivery (enabled by route optimization) increases satisfaction. AI-driven personalization improves recommendations.

The numbers? Higher Net Promoter Scores. Increased customer lifetime value. Reduced customer acquisition costs because satisfied customers require less marketing. That’s the loyalty dividend.

Taking Action Today

Industry leaders have already adopted AI in supply chain. The competitive landscape is shifting rapidly. Companies moving decisively and strategically now will realize the full competitive benefits this technology offers. Those that delay risk falling behind competitors already capturing operational advantages, cost reductions, and customer satisfaction improvements.

So here’s your move: Assess your current supply chain maturity. Build a business case showing projected costs, timeline, and expected returns. Secure executive sponsorship. Launch a pilot within 90 days targeting 10-20% improvements in your chosen metrics.

The future of retail supply chain management is AI-driven. The question isn’t whether to adopt it, it’s how quickly you can implement it.