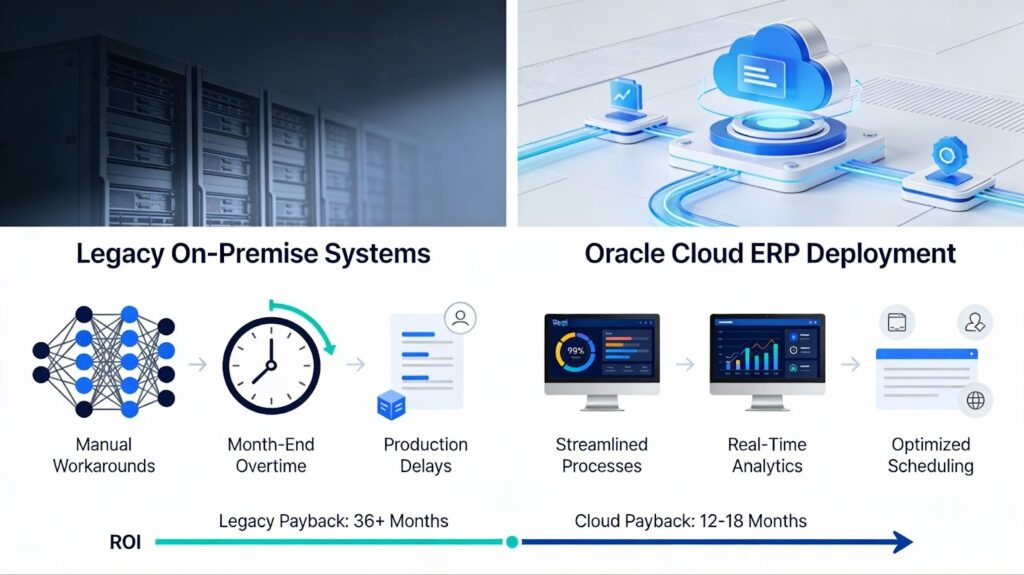

If you lead finance in a manufacturing company, your legacy systems are probably costing you more than you want to admit. Not just in license fees, but in the overtime your finance team racks up at month-end, the workarounds your supply chain team has built over the years, and the production decisions your plant managers make without real-time data. That hidden cost is exactly what drives many CFOs to take manufacturing cloud migration seriously.

Over the last decade, Oracle has invested heavily in cloud ERP for product-centric industries, including manufacturing, with a clear focus on measurable financial outcomes. Oracle and Nucleus Research outline structured ways to calculate ERP return on investment, showing that cloud deployments often outperform on-premise by a wide margin.

For CFOs, the core question is simple: what does Oracle Cloud ROI really look like in a manufacturing context, and how quickly can you see it on the P&L?

Why manufacturing cloud migration is back on the CFO agenda

Here’s the reality: staying on legacy ERP is no longer the “safe” option. Analysts and vendors now consistently report that manufacturers moving to cloud ERP cut operating costs, improve agility, and get better visibility across the value chain. In other words, cloud modernization is not just an IT upgrade; it is a financial strategy.

From what various manufacturing case studies show, cloud ERP helps in three very concrete ways:

- You reduce infrastructure and support costs as you retire aging servers, data centers, and middleware.

- You gain end‑to‑end visibility across production, inventory, and finance, which makes planning less guesswork and more data-driven.

- You shorten cycle times for key processes like order-to-cash, procure-to-pay, and month-end close.

Nucleus Research and other industry analysts have found that cloud deployments can deliver multiples of the original investment compared to traditional ERP, especially when the implementation is carefully scoped and aligned with operational priorities. For CFOs, this is where Oracle ERP cost benefits start to look compelling: lower total cost of ownership, better insight, and the ability to reallocate people to higher-value work.

The five pillars of Oracle Cloud ROI for manufacturers

Every CFO evaluating Oracle Cloud ROI in manufacturing should look at five main pillars. Together, they turn a vague “digital transformation” promise into a concrete financial story.

I. Direct cost reduction

First, you have the obvious cost savings. Moving to Oracle’s cloud platform means:

- Shutting down or downsizing on-premise data centers

- Reducing hardware refresh cycles

- Simplifying software licensing and maintenance contracts

Vendors and service partners regularly cite 20-40% reductions in infrastructure and related support costs once organizations complete manufacturing cloud migration and decommission their legacy stacks. Those savings hit the bottom line quickly and form the foundation of your Oracle Cloud ROI.

II. Operational efficiency and process automation

The second pillar is process efficiency. After reviewing dozens of ERP implementations, research shows that manufacturers can cut manual work and cycle times significantly by automating workflows and standardizing processes in cloud ERP. For example:

- Closing the books can move from 18-20 business days down to 3-5 days in many cases

- Real-time production and inventory visibility reduces rework, stockouts, and expedited shipping.

- Automated approvals and integrated data flows shrink bottlenecks across finance, procurement, and operations.

These gains translate into fewer hours spent on low-value tasks and more time for analysis, which is central to CFO digital transformation.

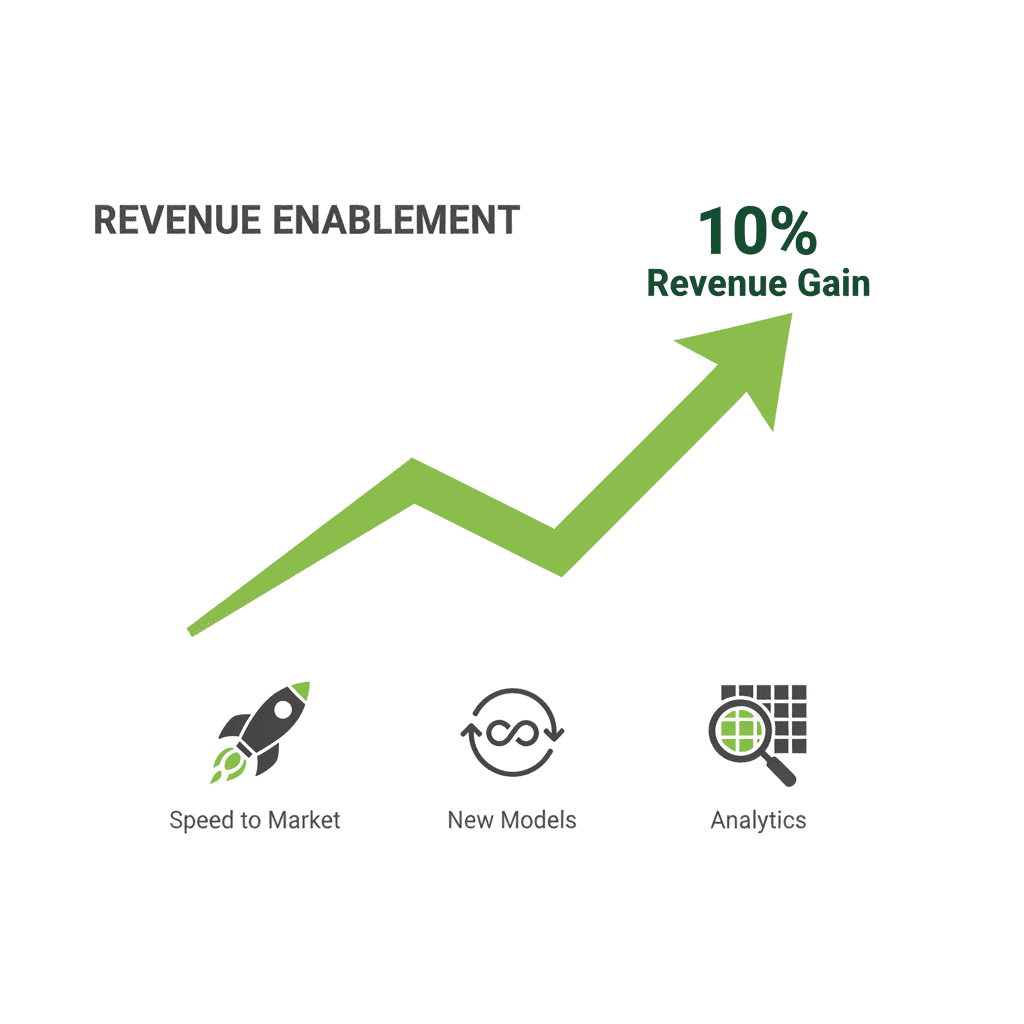

III. Revenue enablement and growth

Oracle Cloud ROI is not just about cost cutting. Cloud modernization also helps manufacturers generate more revenue by:

- Getting new products to market faster with streamlined product and BOM data flows

- Supporting new business models like direct-to-customer or subscription-based services

- Providing analytics that improve pricing, discounting, and customer profitability decisions

Industry discussions suggest that, when cloud ERP is implemented alongside better analytics and planning, incremental revenue gains of 5-10% over a few years are not unusual for mid-market and larger manufacturers.

IV. Risk reduction, compliance, and resilience

The fourth pillar often gets overlooked in spreadsheets but matters to boards. Cloud ERP strengthens controls, standardizes processes, and makes audits easier with centralized data and embedded compliance features. Cloud providers also invest heavily in security, uptime, and disaster recovery, far more than most individual manufacturers can justify on their own.

That reduction in risk rarely shows up as a single line item, but it changes your risk profile and improves resilience, which is critical in a world of supply chain shocks and regulatory pressure.

V. Strategic agility and CFO digital transformation

Finally, there is agility. Oracle’s cloud platform for manufacturing integrates ERP, supply chain, and emerging technologies like AI and predictive analytics. For CFOs, that means:

- Faster access to consolidated financial and operational data

- The ability to model scenarios quickly

- A better partnership with operations, IT, and the board

This strategic agility is central to CFO digital transformation. It is harder to quantify but becomes visible in faster decision-making, better capital allocation, and fewer “surprises” at quarter-end.

Real-world style scenario: What can Oracle Cloud ROI look like?

To make this more concrete, imagine a mid-sized automotive components manufacturer with about $200M in annual revenue. The company runs a heavily customized on-premise ERP, plus separate systems for manufacturing execution and quality management.

Based on patterns in published Oracle and partner case studies, as well as independent manufacturing ROI analyses, a scenario might look like this:

- Initial Oracle Cloud program (ERP + key supply chain modules) totals around $1.2M over 18-24 months.

- Infrastructure and legacy license savings reach roughly $400K-$500K per year once old systems are shut down.

- Process improvements and automation free thousands of hours across finance, procurement, and operations, worth another few hundred thousand dollars annually.

- Better visibility into inventory and production reduces waste and improves inventory turns, releasing working capital and cutting scrap.

When you add those benefits up over three years, the cumulative Oracle Cloud cost benefits can easily surpass the original investment, particularly when you include the revenue side of the equation. Studies from Nucleus and other analysts have shown cloud ERP projects delivering multiple dollars of benefit for every dollar spent when implemented well.

Common pitfalls that slow down Oracle Cloud ROI

Of course, not every project is smooth. The companies that struggle with Oracle Cloud ROI often run into the same issues.

- Underestimating change management: Teams need training, support, and time to adopt new processes. Multiple consulting firms and case studies highlight that projects with stronger change management achieve faster and higher ROI.

- Overlooking integrations: Manufacturing environments rely on MES, PLM, quality systems, and more. If integration to Oracle Cloud is treated as an afterthought, timelines slip and benefits are delayed.

- Misaligned expectations: Some stakeholders expect instant transformation. Most realistic roadmaps show infrastructure savings early, efficiency gains during the first 12-18 months, and more strategic benefits after that.

The honest caveat: this is not “plug-and-play.” It requires clear scope, strong sponsorship, and a realistic understanding of your organization’s readiness for cloud modernization. But done right, the financial story holds up.

Key questions CFOs ask about Oracle Cloud ROI

How long does Oracle Cloud implementation actually take?

For most manufacturers moving core ERP and critical processes, implementation typically spans 12–24 months, depending on scope, complexity, and how aggressively you rationalize legacy customizations. Phased rollouts let you start capturing benefits earlier while reducing risk to production operations.

What is Oracle Cloud ROI for manufacturing?

Looking across independent reports and vendor-backed ROI frameworks, Oracle Cloud ROI for manufacturing often falls in the 60-120% range over three years, with:

- Roughly 25-40% of benefit from cost savings

- Around 30-50% from operational efficiency and automation

- The remainder from revenue uplift and risk reduction, depending on your business model

How long until we break even?

Most manufacturers that plan carefully and fully retire legacy systems tend to reach break-even in 18–24 months. You typically see early savings from infrastructure and support, then incremental gains from process improvement and better decision-making.

A practical ROI framework for CFOs

When you sit down to build your Oracle Cloud ROI calculator, keep it practical and grounded in your reality. A simple but effective approach is to:

- Baseline your current costs: Include infrastructure, software maintenance, support staff, energy, and even “shadow IT” tools your teams have adopted to fill gaps.

- Estimate Oracle ERP cost benefits: Work with your implementation partner to model subscription fees, implementation services, and ongoing support, then compare against the baseline.

- Quantify operational wins: Use realistic hypotheses based on external benchmarks, such as closing days reduced, inventory accuracy improved, or overtime cut, and tie those to actual cost or capacity improvements.

- Add strategic and risk factors: Factor in improved resilience, compliance, and flexibility, even if you treat them conservatively in the financial model.

The basic formula stays simple:

Oracle Cloud ROI = [(Total Benefits − Total Costs) / Total Costs] × 100

What matters more is the quality of your assumptions, the transparency of your methodology, and the alignment with operations. That is where CFO digital transformation becomes more than a buzzword.

Bringing it all together

For manufacturing CFOs, cloud modernization with Oracle is no longer just an IT refresh. It is a way to reclaim budgets stuck in legacy systems, support more agile decision-making, and position the organization for the next decade of competition. The numbers from real-world deployments and independent research consistently show that, when projects are scoped well and supported from the top, Oracle Cloud ROI in manufacturing is both achievable and defensible.

The challenge, and opportunity, for finance leaders is to translate that potential into a business case that reflects your specific plants, products, and people. With the right assumptions, solid benchmarks, and a realistic plan for manufacturing cloud migration, you can move from just keeping legacy systems alive to funding genuine growth and innovation.